Lighting Arrester :

The device used for this is called the lightning arrester or the surge diverter. The lightning arrester is kept at a suitable place in the substation. It is connected between the line and earth as shown in fig.

In normal conditions, the air gap is sufficient for the line voltage so the current does not flow to the earth through the diverter but when the travelling wave comes on the line at the diverter and reaches to some voltage (at point P as shown in figure), the breakdown of air gap occurs and the arc is produced.

So the diverter gives a low impedance path. So the additional charges on the line are grounded. It should be remembered that the surge diverter should give a low impedance path only when the traveling wave comes and not before or after.

The following characteristics are essential in the surge diverter.

1. No current should flow through the surge diverter in normal healthy conditions.

2. Easy path to earth should be given by the surge diverter when the overvoltage comes.

3. The diverter should be capable of withstanding discharge for some period after the discharging of current.

4. The secondary transients should not be produced during its operation.

5. The surge diverter should work normally as before after the transient is suppressed.

6. Impulse ratio = Break down voltage of the wave for the specific time duration / Break down voltage for the 50 Hz wave

If the impulse ratio is unity, it means that the lightning arrester will be able to divert the wave of any time duration.

Types of Lighting Arresters:

1. Rod gap arrester

2. Sphere gap arrester

3. Horn gap arrester

4. Multi gap arrester

5. Expulsion type arrester (protector tube)

6. Electrolytic type arrester

7. Lead oxide type arrester

8. Thyrite type arrester or valve type arrester

Rod gap arrester :

This type of lightning arrester has a simple construction. Two rods of 15 mm diameter are bent at a right angle and kept such that some gap remains between the two rods.

One rod is joined to the line conductor and the other rod is joined to the ground.

The distance P between the insulators and gap should be more than one-third of the length so that the arc occurs away from the insulator when the arc occurs.

The length of the gap is kept such that the breakdown occurs at 80% of the spark over voltage so that the steep wave front does not come on the insulator.

The figure shows the arrangement of the rod gap for transformer and

for the rod gap for the string insulators.

Advantages :

1. Construction is simple.

2. Cost is very less

Disadvantages/Limitations :

1. Arc is maintained even after the surge is suppressed and the normal voltage is restored. This causes a short circuit in the system.

2. Rod can melt due to the heat of the arc.

3. Moisture in the air, temperature, etc, affects the working of the rod gap arrester.

4. Polarity of the surge also affects the working of the arrester.

Due to the above reasons, the rod gap arrester is used only as backup protection.

Sphere gap arrester :

In this two metal spheres are kept near to each other at a certain small distance.

Sphere A is connected to the line and sphere B is connected to the earth.

One choke coil is connected between phase B of the transformer and sphere A so that the overvoltage surge does not go to the winding of the transformer after reflection.

There is no discharge at a normal voltage in the healthy condition.

The air between the spheres breaks down and the arc is produced between the spheres when the overvoltage comes.

The arc goes up due to the heat. Arc continues at the normal voltage and it stops when the voltage is not available when the circuit breaker is tripped.

Advantages :

1. It is less costly.

2. The impulse ratio is unity,

Disadvantages :

Arc does not quench of its own. For this, the circuit breaker is tripped.

So the arc quenches as the voltage is not available. But there is an interruption in the supply due to the opening of the a circuit breaker which is not desirable.

Horn gap arrester:

These are horn-shaped metal rods. One is connected to the line and the other is earthed.

There is an air gap between the two. The horns are mounted on the porcelain insulators.

In the healthy condition at a normal voltage, no arc is produced between the two horns.

Arc is produced across the horns due to the lightning. So the overvoltage surge is grounded.

Due to the heated air the arc goes upward, its length is increased and the arc is quenched.

An inductor is connected between the winding of the transformer and the horn which gives negligible reactance at the power frequency but offers high reactance to the overvoltage due to its high frequency.

So the overvoltage does not affect the winding of the transformer

and is grounded through the horn gap.

Resistance is connected in series with the horn to limit the following current.

Advantages :

1. Arc quenches of its own so the system does not short.

2. Magnitude of the following current decreases due to the series resistance.

Disadvantages/Limitations :

1. Horns can get shorted by external objects like branches of trees, wire etc.

2. Setting of the horn gets affected due to corrosion, pitting etc. so its performance is affected.

3. Operating time is long about 3 seconds.

Due to the above reasons, this type of arrester is not used.

Multi gap arrester :

In this, there are four to five cylinders made of zinc and these are kept at the required distance.

These cylinders are insulated from one another. The first cylinder no. 1 is connected to the line and the last cylinder no. 5 is connected to the earth through the series resistor.

Power arc is limited due to the series resistance and the following current is also reduced.

But by doing so, the protection against the traveling wave is reduced.

To prevent this, a shunt resistance is connected across cylinder nos. 3 and 5.

In normal healthy condition, cylinder no. 3 is at the earth potential through shunt resistance and series resistance R.

Normal supply voltage is not enough to cause breakdown of the series gap.

But in the case of over-voltage, breakdown occurs between cylinders 1 2-3.

Current produced due to the breakdown prefers the straight path through the cylinders 3-4-5 instead of passing through shunt resistance.

The arc is produced across cylinders 3-4-5 quenches when the surge suppresses and the power will be limited by shunt and the series

resistance.

This current is insufficient to maintain the arc in the gap 1 to 3 and the normal condition is restored.

This type of arrester is used up to 33 kV.

Advantages :

1. The construction is simple.

2. Arc does not persist after the normal voltage is restored.

Limitations :

1. Comparatively it is costly.

2. Proper gap has to be adjusted between the cylinders.

3. It is useful up to 33 kV only.

Expulsion type arrester or protector tube :

In this, there is a fiber tube as shown in the figure. Two electrodes are kept in it with an air gap between the two.

The tube is kept such that the top electrode comes below the line conductor.

The lower electrode is joined to the earth. The figure shows the

arrangement for one line conductor. A similar arrangement is made for the other two conductors.

Thus two air gaps are available in each arrangement. When there is overvoltage in the line, the air between the conductor and upper electrode breaks down and similarly, the breakdown of the inner gap also occurs and the arc is produced.

Some fiber in the inner wall of the tube is converted into vapour at high pressure due to the heat of the arc.

This gas comes out through the lower electrode. So the ionized air surrounding the arc also goes out.

Arc is quenched at the current zero and does not restrike.

Advantages :

1. The cost is relatively less

2. There is no power frequency follow current.

3. This can easily be installed.

Disadvantages/Limitations :

1. Some fiber is consumed at every operation so it can be used up to certain numbers of operations. These are to be replaced after some usage so it becomes costly.

2. Gas is liberated when it operates so it cannot be used for closed installations.

3. Volt ampere characteristic is not proper so it is not useful for the costly equipment.

4. It is useful up to 33 kV only.

Electrolytic type arrester:

Such type of arrester is used for high voltage equipment.

Principle:

In this, a thin film of aluminum hydroxide is deposited on thin plate of aluminium.

This plate is kept in electrolytes. Due to this high resistance is obtained at low voltage and power frequency while the resistance becomes very low at high voltage and transient frequency.

The film of aluminium hydroxide gets punctured at overvoltage and a low resistance path is available.

When over-voltage subsides, reformation of the oxide film starts and the current flow stops when the film is formed completely.

There is a critical voltage for this film to puncture.

Construction :

In this some cells are stacked one above the other. If the numbers of cells are N, then

Total critical voltage = Critical voltage of each cell X N

Thus the numbers of cells are used depending upon the voltage.

Advantages :

1. Discharging capacity is high.

2. There is no need of the series resistance.

Disadvantages/Limitations:

1. The operation of this type of arrestor depends upon the formation of the film so it is necessary to check. Maintenance is necessary and it is costly too.

2. The electrolyte freezes in the cold so it is not useful in cold countries.

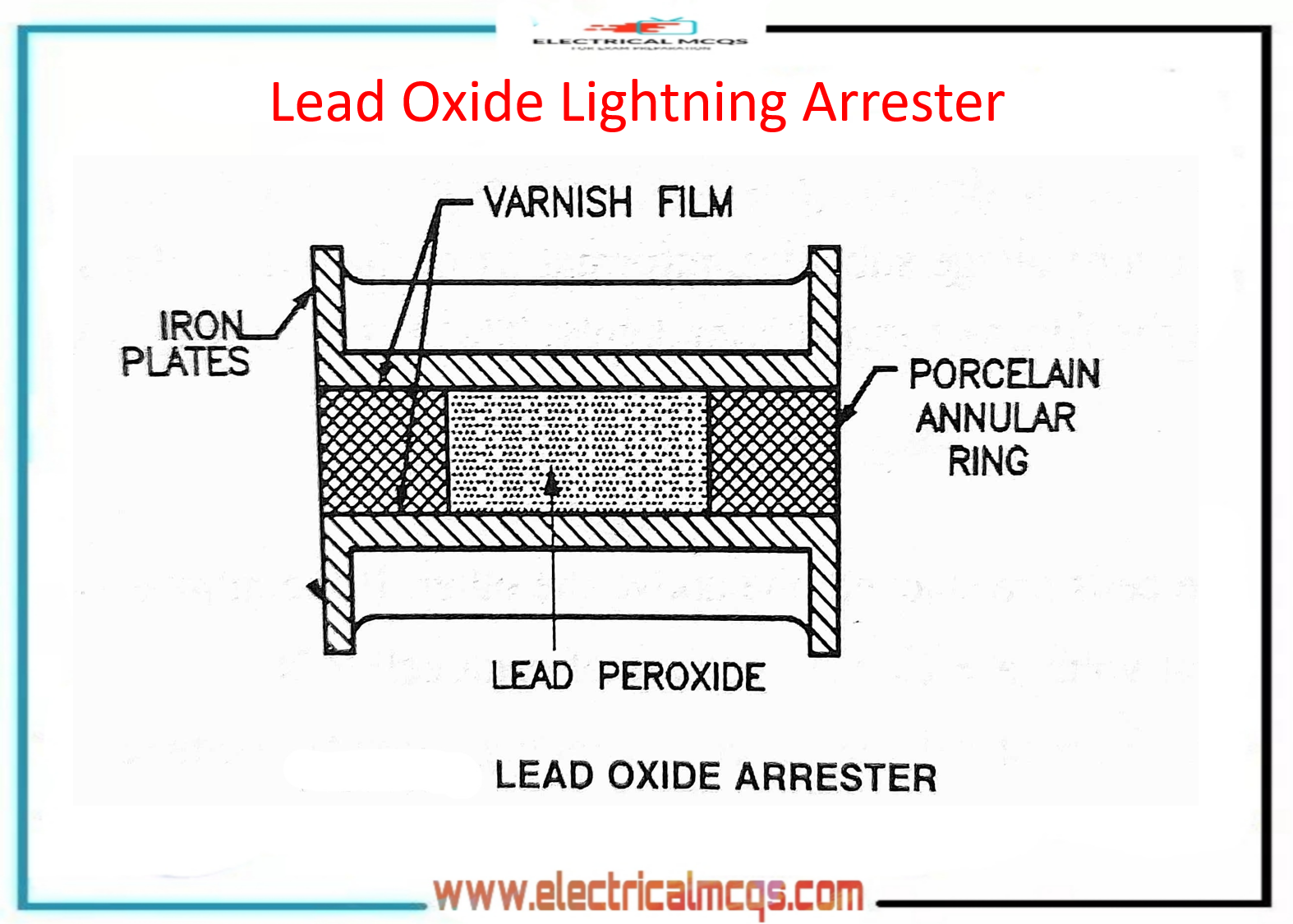

Lead oxide type arrester:

This type of lightning arrester is more effective than the electrolytic type lightning arrester.

Principle :

Lead peroxide is a good conductor of electricity at room temperature but at about 150° C, it becomes the insulator because it is converted into the lead when it is heated

The resistivity becomes 410 ohm-m from 16.4 x 10 -6 ohm- m. It is converted into litharge when it is further heated, which is the perfect insulating material.

Construction :

This type of lightning arrester is in the form of separate discs which are stacked one over the other.

The numbers of a cell depend upon the normal system voltage. The construction of each cell is as follows,

In this there are two circular electrodes of iron one side of which there is coating of varnish.

The coating of varnish breaks down due to the overvoltage and discharge occurs from the lead peroxide.

Lead peroxide is converted in to red lead due to the heat produced

due to passage of current.

Discharge stops due to the high resistance of the red lead. If still

the over voltage is continued, the discharge continues via the other path.

Power current cannot flow to the earth due to the high resistance of red led.

Size of the cell is kept such what it can last for certain numbers of years.

Cell becomes useless when all the lead peroxide is converted in to red lead.

Another type of lead peroxide type lightening arrester is called the pallet type red peroxide lightening arrester.

In this a plate of diameter of 2.4 mm made of lead pallet with

coating of porous litharge is used.

It is used with series spark gap. Single tube is used for 25 kV when the neutral is earthed.

But the rating of the single tube is 18 kV when the neutral

is earthed through inductance.

Required numbers of tubes are joined in series for higher voltage.

Advantages :

1. It does not require day to day care and maintenance.

2. It is especially useful for remote location.

3. First the breakdown of vamish occurs so there is no effect of low value of transient.

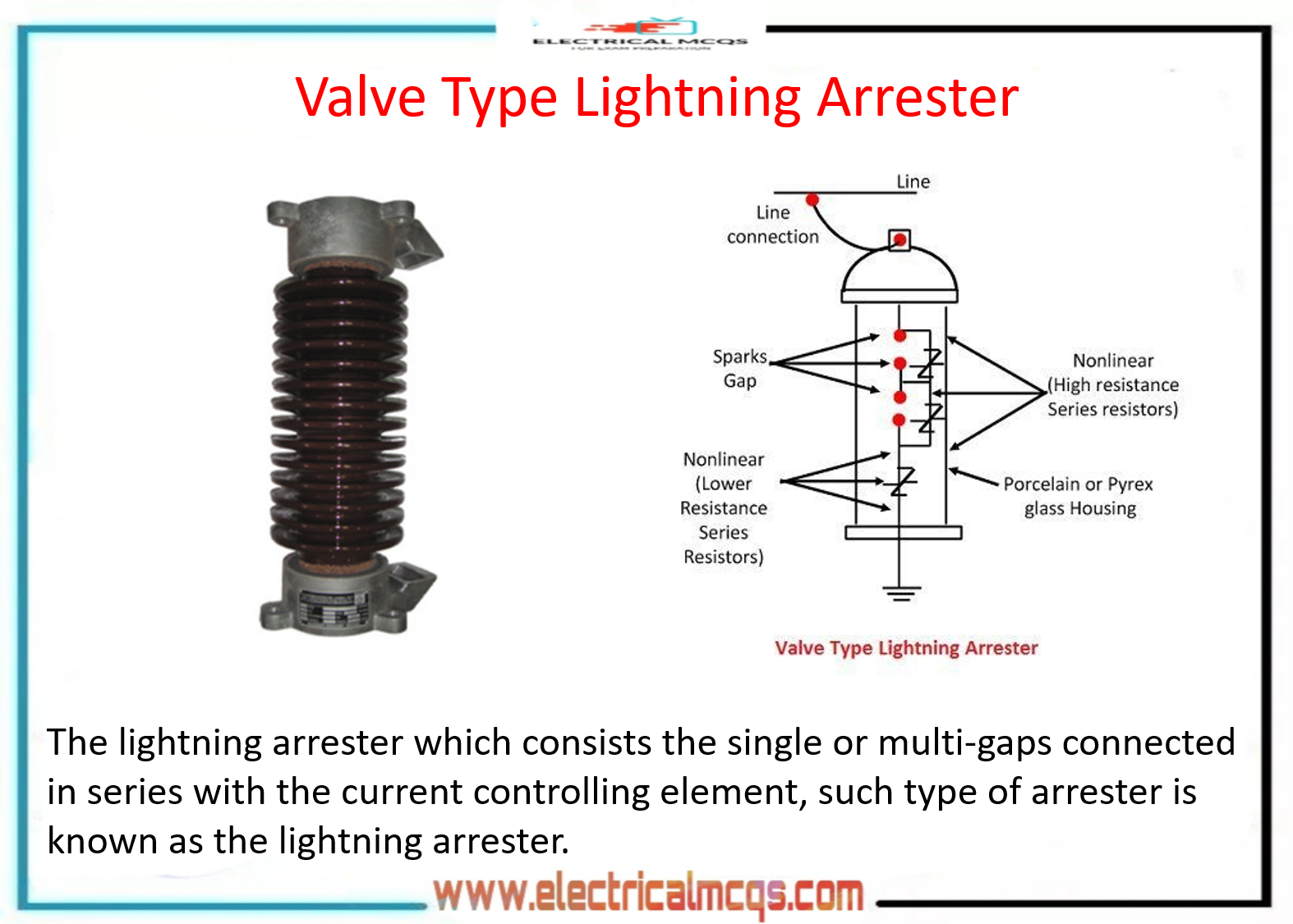

Thyrite lightning arrester or valve type lightning arrester:

Principle :

Carborundum is added in the special type soil and it is heated for specific temperature cycles.

The resulting material is known as thyrite. The important characteristic of thyrite is that it behaves as insulator at certain low voltage and at behaves as conducting material for high voltage.

Thus the electrical resistance of thyrite is dependent on the voltage.

When the voltage becomes double, the resistance becomes so low that the current becomes 12.5 times.

Moreover, the change in conduction of current does not depend on the change in rate of change of the voltage and it is instantaneous.

Moreover the insulating property comes back when the voltage becomes normal.

Construction :

Fig. shows the simple construction of thyrite type lightning arrester.

Each cell comprises of thyrite disc of 160 mm diameter and 17.5 mm thick.

Voltage of each cell is 1 kV. Each cell is sprayed on both the sides.

Such 11 numbers of discs are stacked together to make one unit of 11 kV. It is housed in a porcelain container.

Construction of divider spark gap is made at the lower side. Resistor is kept between the two electrodes.

Watertight cap is provided at the top so that the water cannot enter in.

Line terminal is kept on the upper side and the ground terminal taken from the lower side.

Working :

No spark is produced when there is little change in the line voltage as the effect of resistance is much than the gap.

When the overvoltage comes, the change is rapid so the arc is produced in the gap due to the unbalance capacitance of the gap.

Discharge is grounded as now thyrite offers very low resistance.

Other material Metrosil is also used in place of thyrite.

Advantages :

1. It gives effective protection against the over voltages.

2. It works rapidly (takes less than 1 second).

3. Impulse ratio is almost unity.

Disadvantages/Limitations :

1. It cannot give protection against the steep wave front.

2. Its performance is affected badly due to the moisture.

Applications :

1. Station type lightning arresters are used in power stations and substations up to 220 KV.

2. Line type lightning arresters are used up to 66 kV.