Construction of PRT:

Fig. shows the simplest type of open wire construction of Platinum Resistance Thermometer (PRT).

The platinum wire is wound in the form of spirals on an insulating material such as mica or ceramic. This assembly is fired at a high temperature to assure the annealing of the winding. This assembly is then placed at the tip of the probe as shown in Fig.2. This wire is in direct contact with the gas or liquid whose temperature is to be measured. This gas or liquid however should not be corrosive or conductive.3. The resistance of the platinum wire changes with a change in temperature of the gas or liquid. The maximum temperature measurable in continuous operation is 1000° K i.e.727° C.

4. This type of sensor has a positive temperature coefficient of resistivity as they are made from metals. These are also known as "resistance temperature detectors or RTD". The other metals used are nickel and copper.

5. For many applications the platinum Resistance wire is enclosed in a protective tube. The tube is made of glass, quartz, porcelain or metal. This protects the resistance wire from any mechanical damage or chemical reaction.

6. Resistance thermometers are generally of probe type for immersion in medium whose temperature is to be measured or controlled.

7. The probe is protected by a sheath to produce the complete sensing element.

Working:

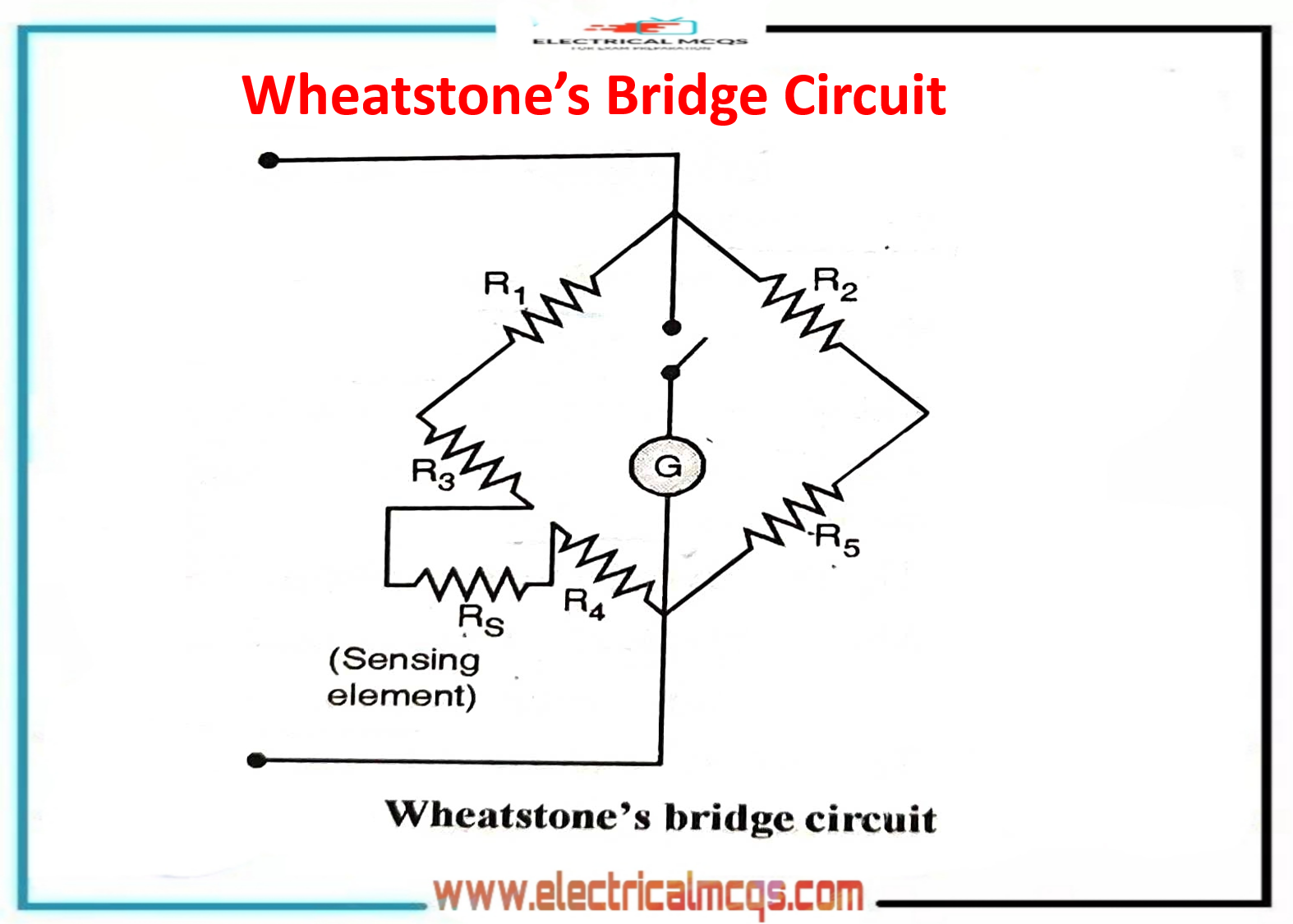

Wheatstone bridge as shown in Fig.

The changes in resistance caused by changes in temperature are detected by a Wheatstone bridge as shown in Fig.The sensing element is made up of conducting material that has a high-temperature coefficient. The resistances R1, R2, and R5 are generally constant under normal temperature changes.

When the bridge is balanced, i.e. no current flows through the galvanometer then the ratio of resistances is,

Practically the sensing element is located away from the galvanometer. Let its leads have resistances R3, R4. Then,

Thus, if resistance Rs changes, the bridge balance cannot be maintained.

The galvanometer will deflect. The amount of deflection is proportional to the temperature.

The wheel type of resistance element enclosed in a stainless steel or platinum tube is as shown in Fig. This is one of the most common types of constructions used in practice.

This probe is used to measure the temperatures of high speed, electrically conductive, or corrosive type liquids.If the temperatures below 80° K are to be measured then the tube is filled with “helium" to avoid conduction of air.

The resistance element is kept in a rod-shaped protective tube.

Advantages :

1. They can be used for the measurement of small as well as large temperature differences.

2. The measurement has a high accuracy.

3. The measurement has a high reproducibility is its characteristics will remain unaltered.

4. PRTs have a good dynamic response i.e. it responds very quickly to the changes in temperature.

5. It offers a lot of flexibility with regard to the choice of measuring equipment.

6. Temperature compensation is not required.

7. Indicators, recorders or controllers can also be operated.

8. The accuracy of the measuring circuit can be verified by substituting a standard resistor for the resistive element.

9. The resistive elements can be used to measure differential temperature.

10. More than one resistance element can be clubbed to the same recording instrument.

11. They provide extremely accurate temperature sensing

12. The resistive element response time is of the order of 2 to 10s.

13. Stability of performance over long periods of time.

14. The size of the resistive element may be about 6-12 mm in diameter and 12-75 mm in length.

15. The temperature-sensitive resistance element can be easily installed and replaced.

16. The resistance thermometers operate over a wide temperature range (- 200°C to 650°C).

17. The resistance thermometers are best suited for remote indication.

18. Stability of performance over long periods of time.

19. The limits of error of a resistive element are +0.25% of the scale reading.

Disadvantages:

1. Large size

2. Sophisticated instrumentation is necessary for the protection of resistance wire.

3. Low resolution of the order to 7 ohm/°C

4. The external dc power source is required

5. High cost

6. Possibility of self-heating.

7. Need for bridge circuit and a power source.