In a three-point starter, a no-volt release coil is connected in series with the shunt field and the field rheostat, and, therefore, the current flowing through the field is the same current that flows through the holding coil.

Thus if sufficient resistance is cut in by the field rheostat so that the holding coil current is no longer able to create sufficient electro-magnetic pull to overcome the spring tension, the starter arm will fall back to the "OFF" position.

It is this undesirable feature of the three-point starter that makes it unsuitable for use with speed-controlled motors and that has resulted in the widespread application of four-point starters.

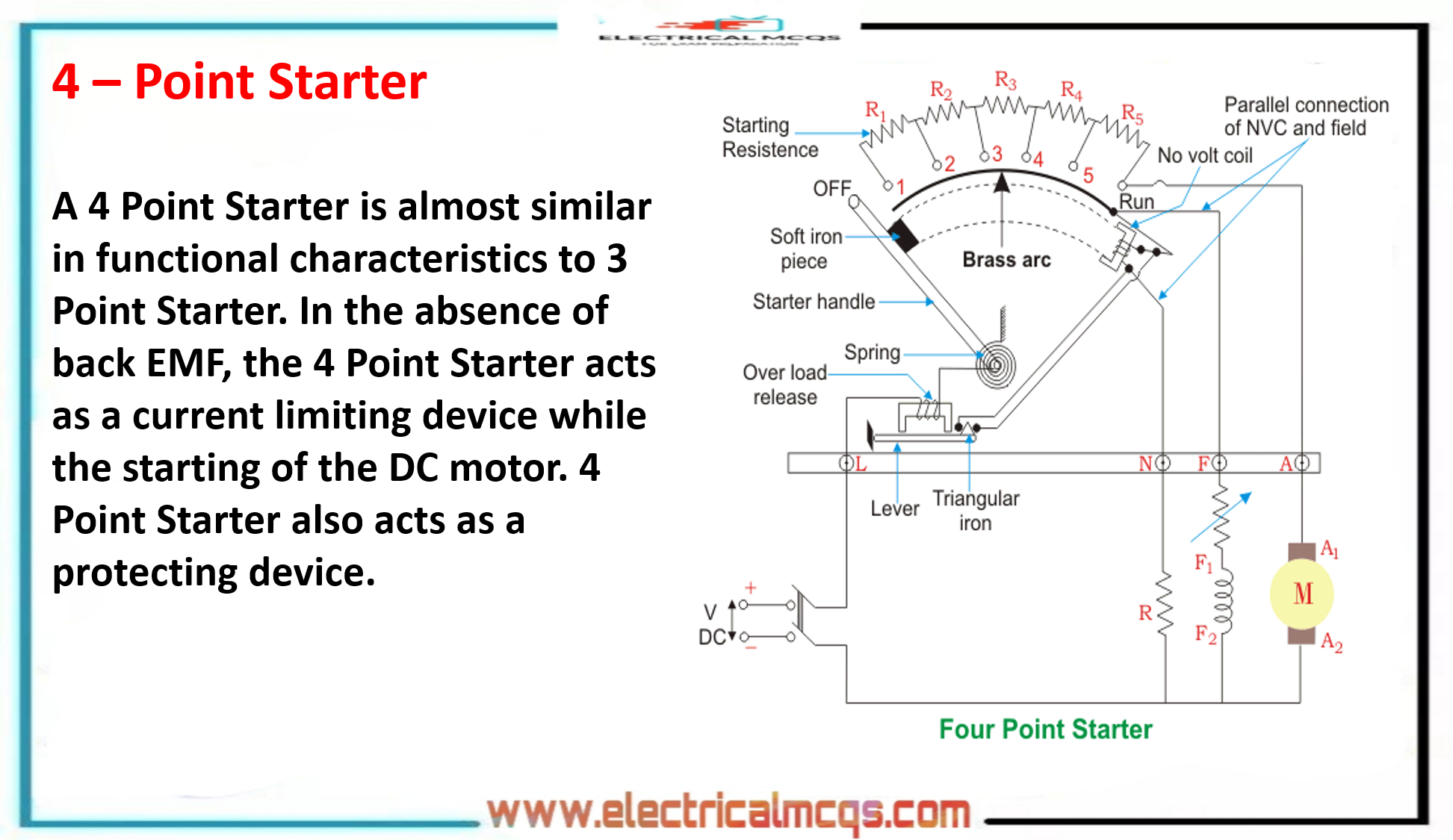

A four-point starter with its internal wiring connected to a long shunt compound wound motor is shown in fig.

From fig. it is obvious that when the arm touches stud no. 1, line current divides into three parts :1. One part passes through starting resistance, armature, and series field.

2. Second part passes through the shunt field winding,

3. The third part passes through a no-volt release coil and protective resistance.

Since in this arrangement, the "no-volt release coil" circuit is independent of the shunt field circuit, it will not be affected by the change of the current in the shunt field circuit.

It means that the electromagnetic pull exerted by the holding coil will always be sufficient and will prevent the spiral spring from restoring the arm to the "OFF" position, no matter how the field rheostat is adjusted.

The possibility of accidentally opening the field circuit is quite remote; hence there is greater acceptance of the four-point starter over the three-point starter.

A motor is started with a four-terminal starter in the same way as with a three-terminal starter. Any desired speed, above normal, of the motor, can be obtained by adjustment of the field rheostat in series with the shunt field.

It is necessary to ensure, before starting a dc motor that the field circuit is closed, the rheostat in series with the shunt field winding is at zero resistance position, and starting resistance in series with the armature circuit is at maximum value.

For stopping the motor, the line switch should always be opened rather than throwing back the starting arm.

In shunt motors, the line switch can be opened without any appreciable arc, since the motor develops a back emf nearly equal to applied line voltage and the net voltage across the switch contact is small.

The electro-magnet energy stored in the field does not appear at the switch but is discharged gradually through the armature.

On the other hand if the starting arm is thrown back the field circuit is broken at the last contact button.

Owing to the inductive nature of the field, this will cause a hot arc and burn the contact.

Precaution:

While stopping the motor, all the resistance in the field rheostat is cut out, so that motor speed falls to its normal value; then the line switch is opened.

This procedure ensures that the next time the motor is started, it will be with a strong field and resultant strong starting torque.