It is a gas and oil actuated protective device and is used practically in all oil-immersed transformers with the exception of smaller distribution transforms. Buchholz relay is used for the protection of the transformer against faults developed inside the transformer. The device relies on the fact that an electrical fault inside the transformer tank is accompanied by the generation of gas, and if the fault current is high enough by a surge of oil from the tank to the conservator.

The Buchholz relay is particularly useful in that it is capable of detecting fault conditions of very low magnitude such as inter-turn faults, incipient winding faults, and core faults due, for example, to core bolt insulation failure which gives rise to short circuit and subsequent arcing and gas.

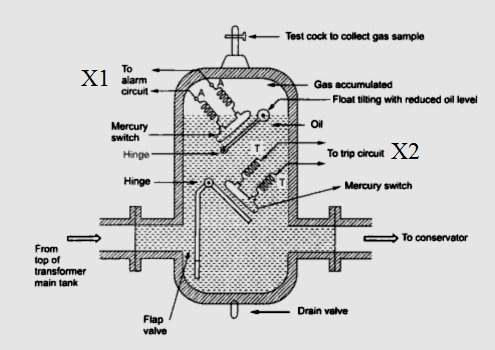

The use of a Buchholz relay is possible only with transformers having conservators and the relay is placed between the transformer tank and the conservator as shown in Fig.

A Buchholz relay consists of an oil-filled chamber as shown in Fing. It contains two floats, the top float F¹ and the bottom float F². Both the float are hinged so as to be pressed by their buoyancy against two stops. When there float sink, each of them short circuits two contacts thereby closing a circuit which gives a warning about the fault.

The operation of the Buchholz relay can be explained as under:

In case a fault occurs, gas bubbles are generated in the transformer tank on account of increased heating produced by faults currents. These bubbles rise and go towards the conservator through the pipeline. The gas bubbles are trapped in the upper part of the relay chamber and since the chamber is full of oil, the oil is displaced which lowers the top float F¹. The float sinks ultimately thereby causing the closure of contacts of the "alarm circuit".

A small window in the wall of the relay chamber shows the amount of gas trapped and its colour. A sample of the gas may be withdrawn and analysed. The amount of gas is indicative of the severity of the fault while the colour of the gas indicates the nature of the fault since the faults occurring in cores and windings produce gases of a different colour.

In case the fault is not severe, the generation of gas is not sufficient so as to lower the level of oil to the extent to affect the bottom float F². Therefore, in the case of mild faults inside the transformer, the bottom float F² remains unaffected.

However, in the case of severe faults, such as short circuits between phases or to earth and faults in the tap changing gear, the gas production becomes violent and cause a surge which causes the bottom float F² to fall and close the contacts of a "trip circuit". This trip circuit energizes the relay of a circuit breaker which open circuits the transformer thereby clearing the fault.